World War II

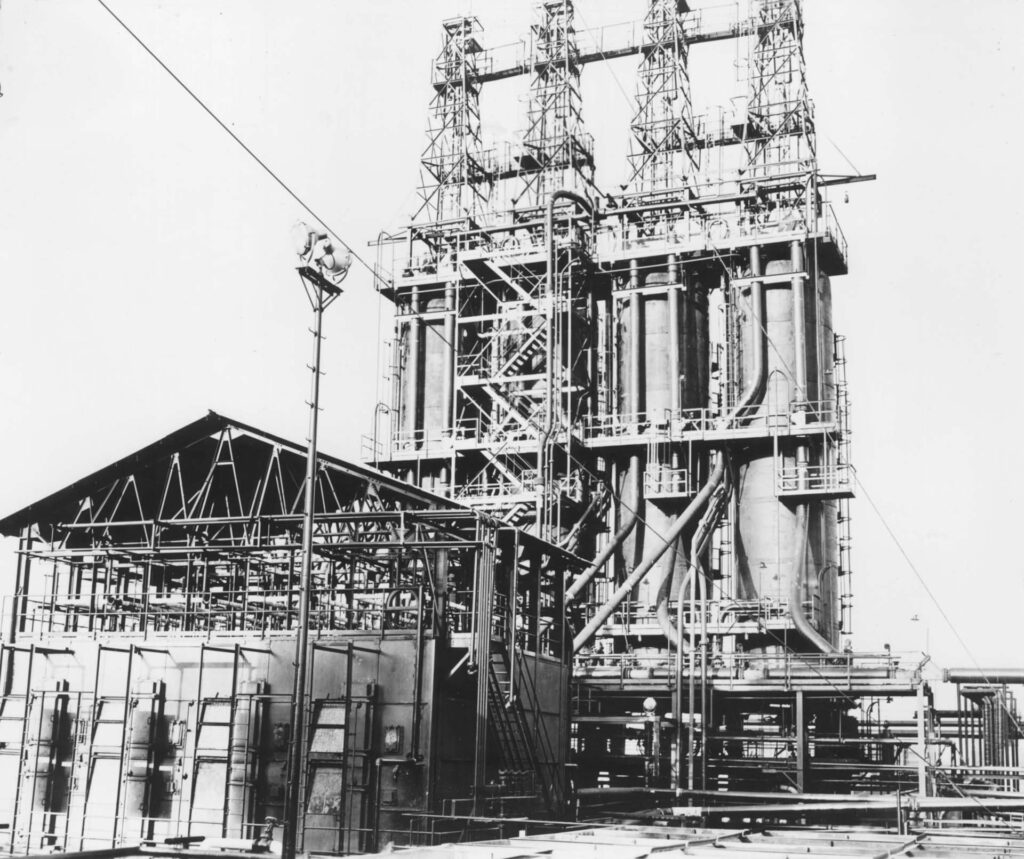

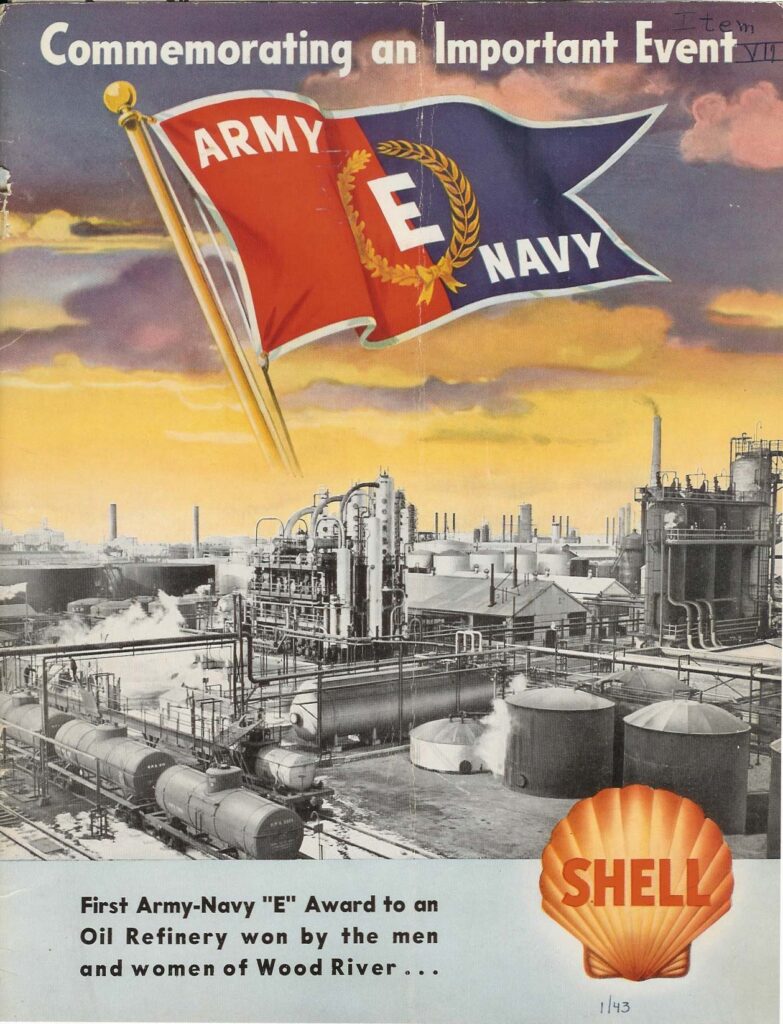

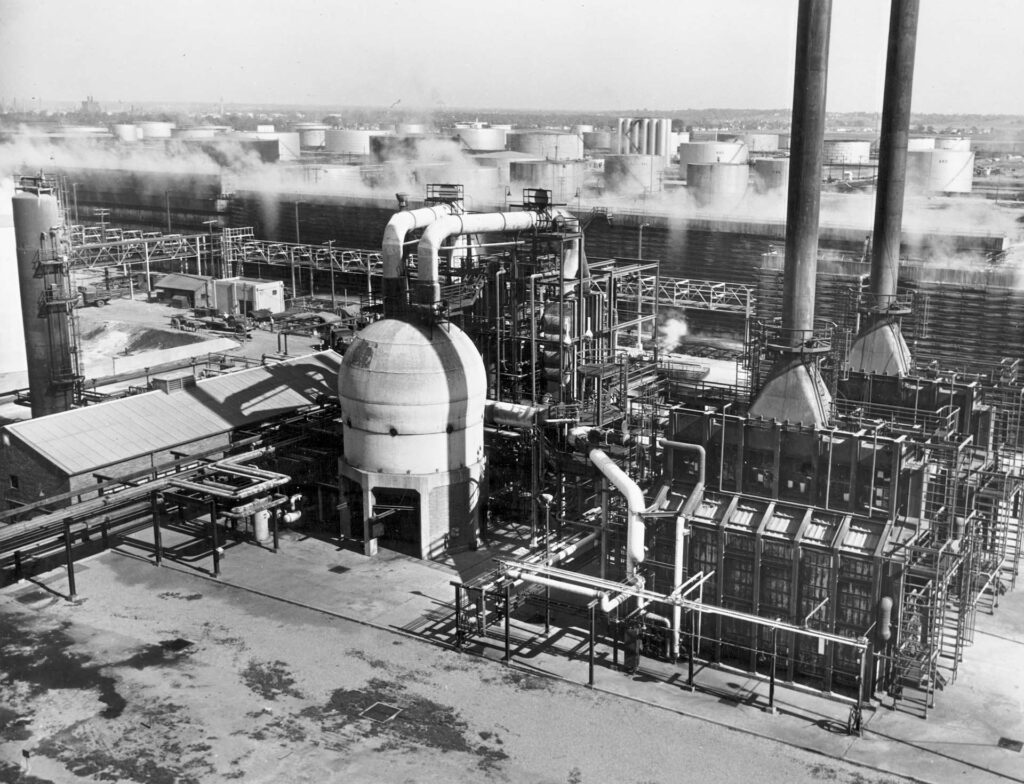

While gasoline was rationed back home, gasoline, diesel and fuel oil were in great demand for the vehicles, airplanes, and ships used in the war effort. The last Dubbs thermal cracking unit, far surpassing the original, was constructed. Then two towering fluid catalytic cracking units, utilizing a new process to produce gasoline from heavier crude oil components, were built (they are still in operation after many improvements). Two alkylation units were built to make gasoline from the lighter compounds in crude oil, utilizing sulfuric acid as a catalyst*. Two toluene plants were built to produce the raw material for TNT, which was shipped to the Weldon Spring, Missouri munitions plant. WRR was the first refinery to win the Army-Navy “E” award for wartime production excellence (WRR would subsequently win it four more times). 793 refinery employees were serving in the armed forces in 1944. Refinery capacity was 90,000 barrels per day in 1945. Expansion continued after the war with the construction of a vacuum flasher unit to produce fuels from the heaviest components of crude oil. Meanwhile, Shell consolidated the headquarters of its various U.S. subsidiaries and moved its corporate offices to New York City. The Shell Building in St. Louis still stands and was converted to a hotel.

Meanwhile, the Wood River Oil and Refining Company constructed its first refinery in nearby Hartford.

*a catalyst promotes a chemical reaction but does not become part of the product