Energy conservation and high tech

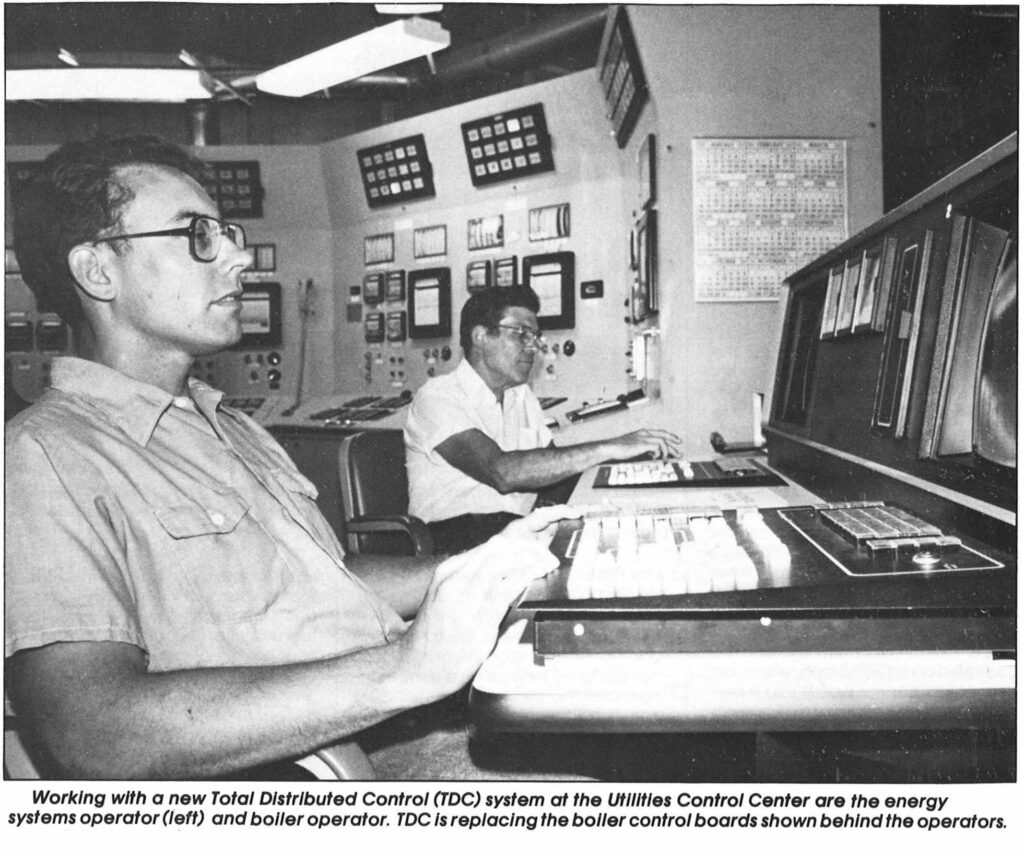

Wood River Refinery was renamed Wood River Manufacturing Complex (WRMC) to recognize that, besides fuels and lubricants, chemicals were being manufactured by the Benzene, Precursor, and new DMK (DiMethyl Ketone) units. A Major Projects organization was created to manage numerous energy conservation projects. To house their personnel, a single-story building was constructed where Dubbs 17 & 18 previously stood. Honeywell TDC 2000 control systems replaced electronic & pneumatic controls for the Boiler House, Distilling Units 1 & 2, Gas Plants, and Alkylation Unit. Digital Equipment Corporation VAX minicomputers provided advanced process control strategies. Large additions to the control rooms were required to house the equipment. Computer terminals, all connected to an IBM 4300 mainframe, were installed throughout the refinery for PROFS email and IMPAC/EPIC spare parts management. Personal computers also began being used, but networking and the internet were in the future.

The Standard Oil refinery in Wood River was shut down and dismantled.

1980s Newsletters: